Surfaces & Coatings

Explore the difference between Maintenance and Transitional Coatings and the advantages of each.

Textures

Visual & tactile

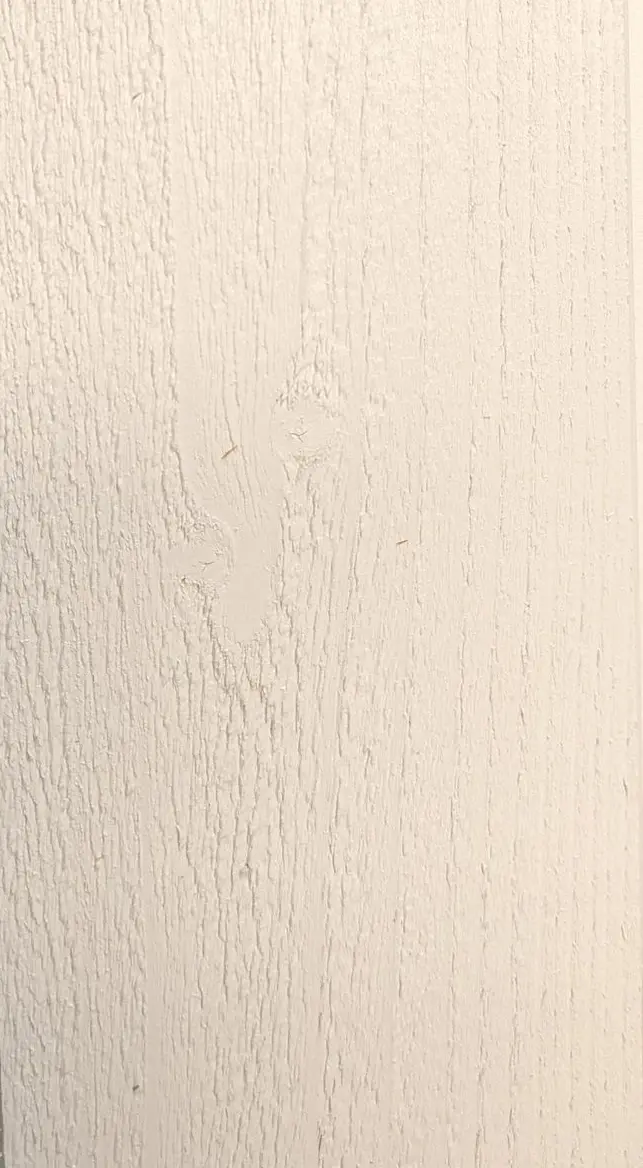

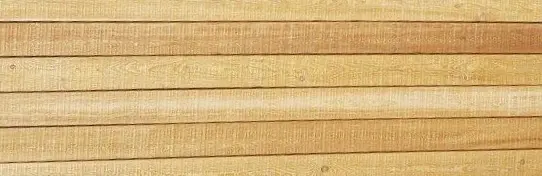

Brushed

Created by wire brushing to remove soft fibres and expose the harder grain, this texture gives timber a rustic, weathered look. Especially effective on softwoods, it enhances grain character and adds a tactile, natural feel suited to traditional or rustic designs.

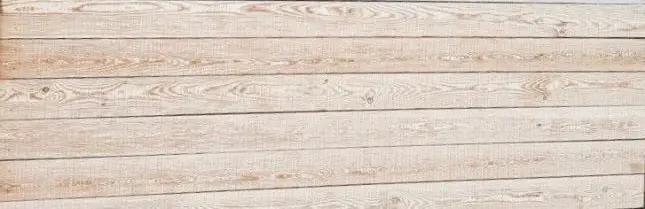

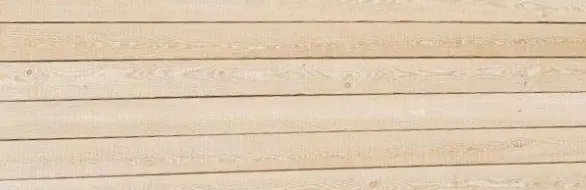

Fine Sawn

Fine sawn texture is produced by cutting along the grain with a bandsaw, leaving rough, linear markings. This finish offers a raw, authentic look that adds warmth and a sense of craftsmanship. It’s ideal for traditional styles and can improve coating durability.

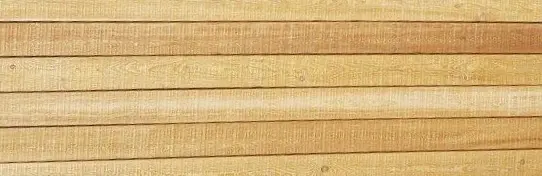

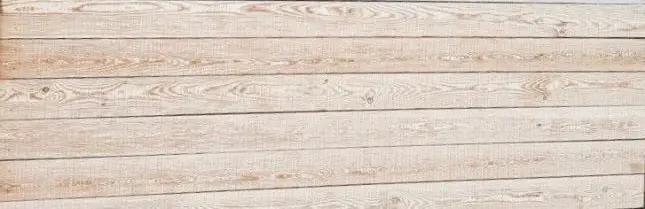

Planed

A smooth, even surface achieved by machine-planing, this finish highlights the timber’s natural grain and colour. It creates a clean, contemporary look that suits modern or minimalist architecture, delivering a polished and refined aesthetic.

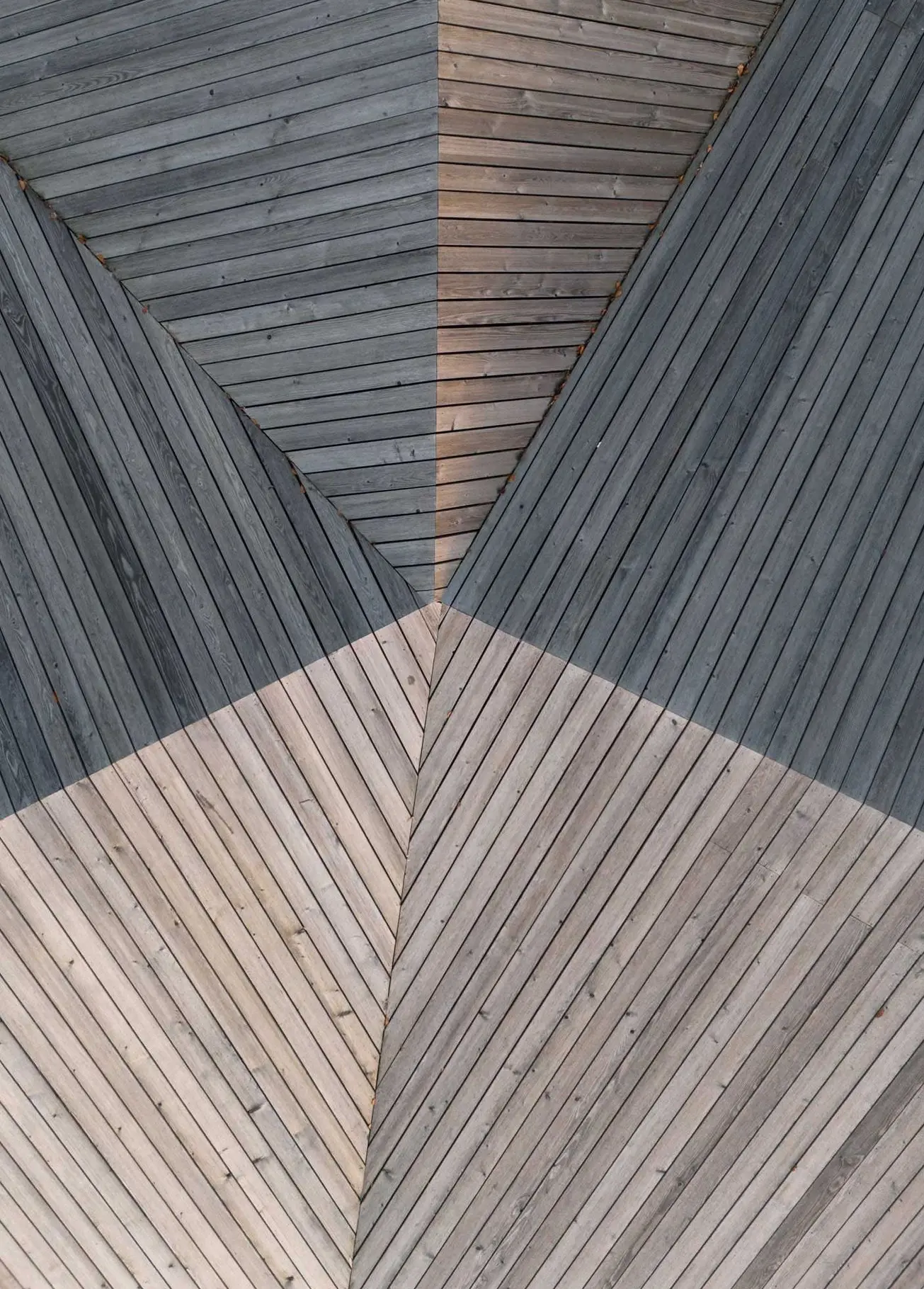

Charred Cladding

Charred timber cladding, an ancient Japanese technique known as Yakisugi, involves charring the surface of wood to create a unique, visually striking, and durable exterior finish. The charring effectively creates a layer of carbon that acts as a shield, making the wood more resistant to fire, weathering, rot, and pests.

Charred & Oiled

After charring, the timber is carefully oiled to enhance its unique cracked texture and deepen the rich charred colour. This process creates a striking, durable, low-maintenance exterior finish that highlights the beauty of the charred wood while providing long-lasting protection.

Charred, Brushed & Oiled

After charring, the wood is brushed to remove softer fibres, revealing a textured grain with added depth and character. It is then oiled to enrich the colour and protect the surface, combining a tactile, visually impactful finish with enhanced durability and weather resistance.

Maintenance coatings to preserve and enhance

Leaving cladding unfinished is perfectly acceptable, but many opt for a coating to enhance appearance or boost durability. Coatings help protect against moisture and UV damage, extending the timber’s lifespan while preserving its colour and visual appeal.

Maintenance coatings protect timber by repelling water, helping prevent rot, warping, and structural damage. They also shield against UV rays, slowing fading and greying. Microporous coatings like oils or silicon-based products allow moisture to escape, boosting durability.

To alter cladding’s appearance post-installation, semi-transparent or opaque coatings add colour while enhancing the wood’s grain and character. These finishes boost visual appeal and offer UV protection -darker tones provide greater defence, reducing future maintenance needs.

Many prefer to preserve timber’s natural beauty and prevent weathering with clear oils or translucent coatings matched to the wood’s shade. These require frequent maintenance. Choosing the right coating depends on timber type and conditions; coatings need dry timber (under 20% moisture) for best results.

Transitional coatings for consistent colouring

When left uncoated, timber weathers to a silver-grey colour over time, but how quickly and evenly this happens depends on factors like location, aspect, and building design. Sheltered areas may weather unevenly or patchily, sometimes never fully evening out.

A Transitional (or 'pre-weathered') coating solves this by instantly providing a consistent weathered look, mimicking years of natural aging. This prevents uneven weathering and speeds up the natural transition. For species prone to patchy surfaces or tannin stains, a dark transitional coating can conceal marks, offering a cleaner, more refined finish.

7 Months

5 Months

1 Month

3 Months

New

Transitional coatings for consistent colouring

When left uncoated, timber weathers to a silver-grey colour over time, but how quickly and evenly this happens depends on factors like location, aspect, and building design. Sheltered areas may weather unevenly or patchily, sometimes never fully evening out.

A Transitional (or 'pre-weathered') coating solves this by instantly providing a consistent weathered look, mimicking years of natural aging. This prevents uneven weathering and speeds up the natural transition. For species prone to patchy surfaces or tannin stains, a dark transitional coating can conceal marks, offering a cleaner, more refined finish.

New

1 Month

3 Months

5 Months

7 Months

Get hands on!

Request your samples here